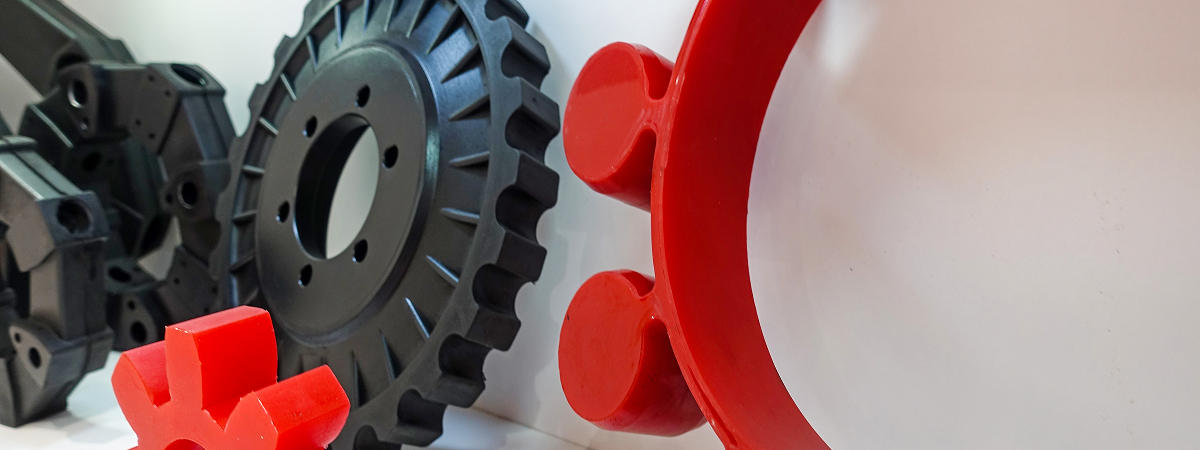

In the rubber industry, talc powder is used as a reinforcing filler and processing aid. It is added to both natural and synthetic rubber compounds to enhance their properties such as elasticity, tensile strength, dimensional stability, heat resistance, and mold release. Its inclusion improves the performance, durability, and cost-effectiveness of rubber products across various industries.